DMJ Series Water-based Barrier Coating

DM TECH

Performance Characteristics:For paper surface coating; waterproof, oil-resistant, heat-sealable, food contact safe, non-blocking, printable, overprintable

Application Scenarios:The coated paper can be made into paper straws/cups/bowls/plates, disposable tableware packaging bags, hotel supplies individual packaging bags, airline vomit bags, courier bags, electronic product outer packaging, etc.

Recommended Coating (dry weight):4-20g/㎡

DMJ 5940 Water-based Heat-sealable Barrier Coating (Base Coat)

performance feature:For thick paper coating; waterproof, highly resistant to oil, heat-sealable, suitable for food contact, prone to re-sticking, requires use in conjunction with surface coating.

application scenarios:The obtained coated paper can be used to make paper straws, paper cups, paper bowls, paper plates, etc.

Recommended coating (dry weight):4-6g/㎡

Performance Characteristics:For thick paper surface coating, waterproof, heavy oil-resistant, heat-sealable, food contact safe, non-blocking, can be used in conjunction with base coating, or can be used separately

Application Scenarios:The coated paper can be made into paper straws/cups/bowls/plates, etc.

Recommended Coating (dry weight):2-4g/㎡

DMJ 3400 Water-based Barrier Coating for Oil-resistant Paper

Performance Characteristics:For thick paper surface coating; waterproof, oil-resistant, food contact safe, fold-resistant, non-stick to molds when paper base is hot pressed (high temperature resistant)

Application Scenarios:The coated paper can be used to make trays for fresh vegetables/fruits/meat, etc.

Recommended Coating (dry weight):4-8g/㎡

Heat Seal Conditions:No heat seal function

Sealing conditions:No heat sealing function

Performance Characteristics:For thin paper surface coating; waterproof, heat-sealable, food contact safe, non-blocking

Application Scenarios:The coated paper can be made into disposable tableware packaging bags/pharmaceutical packaging bags/toy packaging paper bags, etc.

Recommended Coating (dry weight):3-5g/㎡

DMJ 3600 Water-based Printable Barrier Coating (Specifically for Cold Cup Outer Layer)

performance feature:For thick paper coating; waterproof, suitable for food contact, non-reverse adhesion, printable

application scenarios:The obtained coated paper can be used to make cold drink cups, packaging boxes for frozen meat and seafood, packaging bags for frozen fast food, ice cream, etc., for cold and frozen food packaging.

Recommended coating (dry weight):3-5g/㎡

Sealing conditions:No heat sealing function

performance feature:For thin paper coating; waterproof, highly resistant to oil (KIT > 12), suitable for food contact, non-sticky

application scenarios:The obtained coated paper can be used for packaging bags for hamburgers/fried foods, as well as food oil-proof paper without the need for heat sealing.

Recommended coating (dry weight):3-5g/㎡

Sealing conditions:No heat sealing function

DM TECH

Passed Testing

Complies with US FDA 21 CFR176.170

Complies with EN71-3 Heavy Metal Testing

Complies with REACH 224+1 Items Testing

Complies with PFOA; PFOS Perfluorinated Compounds Testing

Complies with Repulping Performance Testing

Complies with Plastic-free Component Analysis Testing

Complies with GB4806.8

Complies with GB9685

Other Testing

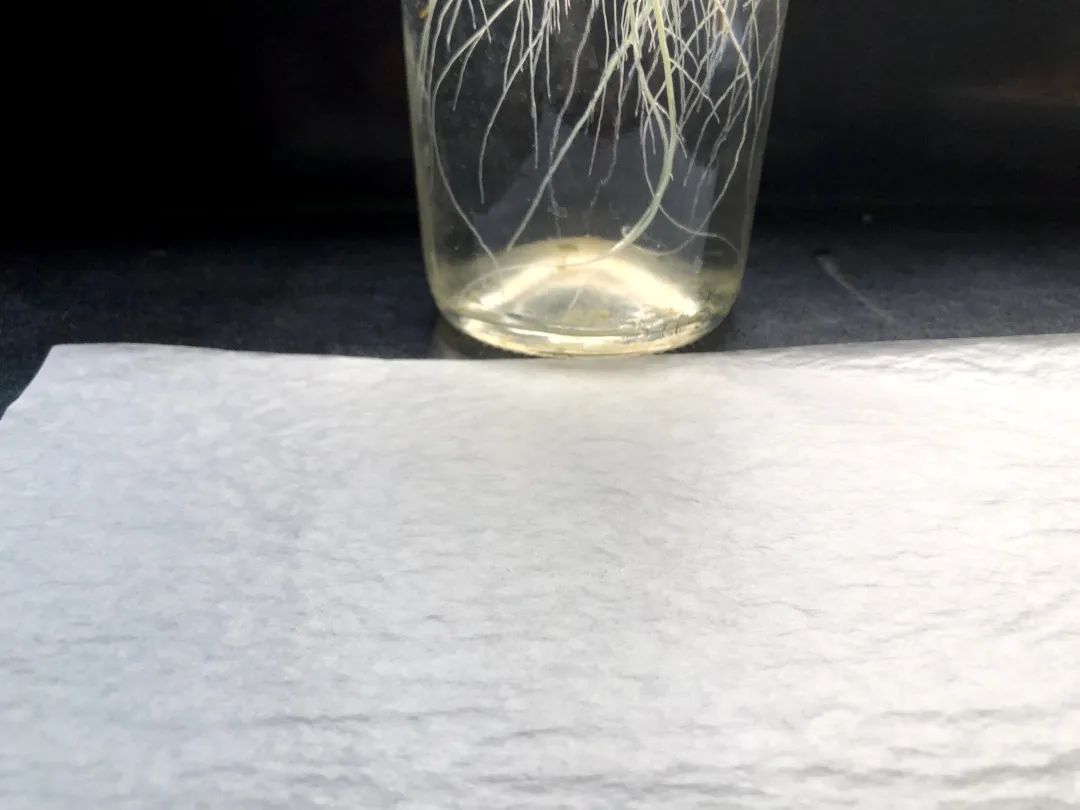

Paper materials coated with DMJ series products for packaging containers:

● Pour 100°C boiling water / hot coffee / hot tea into paper-based containers, cool to room temperature;room temperature;

● Pour 0°C ice water (volume ratio 1:1) mixture into paper-based containers, cool toroom temperature;

● Pour 0°C lemon juice / ice cubes (volume ratio 1:1) mixture into paper-based containers, cool toroom temperature;

● Pour 100°C oil-water (volume ratio 1:1) mixture into paper-based containers andplace in a 65°C oven for 5 hours;

● Put french fries and 10% hot oil into paper-based containers and place in microwavein heating mode for 2 minutes;

Test results: The tested packaging containers have good appearance and no leakage.