Physical Properties

-

• Appearance: Green emulsion

-

• Solid content (weight): 45±2%

-

• Density (kg/L): 1.03

-

• BROOKFIELD Viscosity: 10000-20000 MPA.S

-

• PH Value: 7.0-8.0

-

• Adhesion: Passes 3M tape test

-

• Water Resistance: No significant change after 200 washes with soap water

-

• Abrasion Resistance: No substrate exposure after 100 sandings with 360-grit sandpaper

-

• Heat Resistance: No significant change after infrared drying at 150︒C

-

• Peelability: Can be completely peeled off without residue after initial opening

Application Method

1. Remove dust, grease and other contaminants from plate surface before coating;

2. Screen printing: Use 800-1000 mesh screen, 55° blade at about 45° angle;

3. During printing, scrape 1-2 times with the blade. Ensure each layer is completely dry (recommended drying: 80℃-150℃, 2-3 drying oven cycles) before next layer. First layer DY315 usage is about 30g/㎡ wet film (typical usage: 90-120g/㎡);

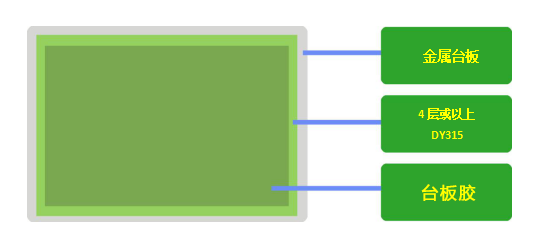

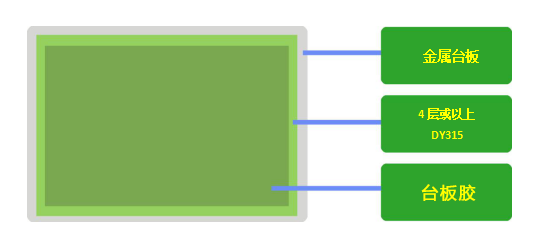

4. For easy removal and durability, recommend printing 4 or more layers (each layer must be dried);

5. For new metal plates or one-time use plates, wipe plate with DY 330 pretreatment liquid first, then follow above steps after surface drying.

Product Performance:

① Washable (soap water) to remove fabric debris, primer won't curl, wrinkle or peel, can be washed repeatedly.

② Heat resistant, can withstand pressing below 250℃ without bubbling or wrinkling, can be peeled normally.

③ Usage cycle: One application lasts at least as long as printing plate paper under normal conditions.

④ Peelability: Can be peeled off completely without breaking or residue.

Application Structure:

Potential Issues and Solutions:

1. Adhesive transfer.

Potential Issues and Solutions:

1. Adhesive transfer.

Cause: Adhesive not fully dried.

Solution: Extend drying time, increase drying temperature.

2. Difficult to peel or can't peel completely.

Cause 1: DY315 coating not fully dried

Solution: Can be used normally after baking, but peel after 4 hours of use

Cause 2: Plate surface (used plates) not cleaned thoroughly, adhesive residue affects peelability.

Solution: Clean plate surface thoroughly with solvent before use. If already difficult to peel, cover primer with wet cloth for half hour before peeling.

Cause 3: Different surface treatments for new plates affect peelability.

Solution: For new metal plates or one-time use plates, wipe plate with DY 330 pretreatment liquid first before using DY315.

Cause 4: Low environmental humidity (below 35%)

Solution: Use humidifier to increase humidity before peeling.

3. Primer delamination or lifting during printing.

Cause: High humidity (above 80%) or incomplete drying causing poor adhesion.

Solution: Extend DY315 drying time, increase drying temperature, dry primer again before use.

4. Can't peel from sandblasted metal plates, imported Portuguese hollow plates or plates with existing leather.

Cause: Primer adheres too well to these substrates.

Solution: Treat surface with DY330 pretreatment liquid before use.

Packaging and Storage

Storage requirements:

Store indoors in cool place, avoid freezing and direct sunlight

Seal after opening, store away from light, dilute with 1%-3% water if viscosity too high

Storage temperature: 0-50︒C

Shelf life: 24 months unopened

Package size: 20KG/drum

Contact Us:

Email:

pzh@dingmaochem.com

Phone: +86-0757-85419909

Fax: +86-020- 84052630

Website: www.dmchem.cn

Address: 3rd Floor,Unit 3,Building 13, Liandong Yougu North Area, Danzao, Nanhai District, Foshan City,Guangdong.